Unveiling the Work Principles and Applications of Pneumatic Rivet Guns

Pneumatic rivet guns, also known as pneumatic riveters, are indispensable tools in various industries, offering efficient and reliable solutions for joining materials together. Understanding their work principles and applications is essential for professionals seeking to optimize their assembly processes.

Work Principles:

Pneumatic rivet guns operate based on compressed air. When activated, the compressed air flows into the gun's cylinder, creating a piston effect. This piston drives the mandrel of the rivet through the hollow rivet body, causing the body to deform and expand against the materials being joined. Once the mandrel reaches its breaking point, it breaks off, leaving the expanded rivet body securely fastened in place.

![抽空沉头pop Pull Thru[1] 抽空沉头pop Pull Thru[1]](https://assets.fengsi.io/api/szent/originals/d9d6b43c-72b1-4f5f-9b95-e6450a00d8dd.gif)

Applications:

Pneumatic rivet guns find applications across a wide range of industries, including automotive, aerospace, construction, and manufacturing. They are commonly used for:

- Assembly Lines: Pneumatic rivet guns are frequently integrated into assembly lines for efficiently joining components and materials.

- Sheet Metal Fabrication: They are ideal for fastening sheet metal panels, ductwork, and enclosures.

- Structural Assembly: Pneumatic rivet guns are used to join structural components, such as beams, frames, and brackets.

- Automotive Repair: In automotive repair shops, pneumatic rivet guns are used for replacing or repairing body panels, trim pieces, and structural components.

Caption

Advantages:

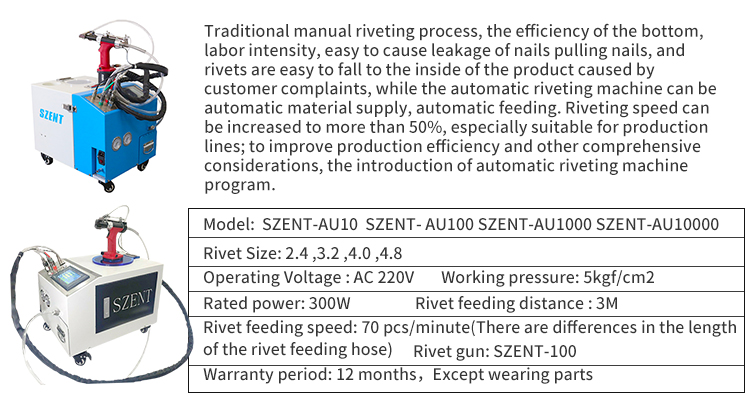

Pneumatic rivet guns offer several advantages over manual riveting methods:

- Efficiency: They significantly reduce installation time compared to manual riveting, improving productivity.

- Consistency: Pneumatic rivet guns provide consistent and uniform rivet installations, ensuring high-quality joints.

- Accessibility: They can reach tight or hard-to-reach spaces, enabling versatile applications.

- Power: Pneumatic rivet guns can generate high pulling forces, making them suitable for a wide range of materials and thicknesses.

Conclusion:

Pneumatic rivet guns are indispensable tools in modern manufacturing and assembly processes. Their efficient operation, versatility, and reliability make them a preferred choice for professionals across various industries. By understanding their work principles and applications, manufacturers and assembly line operators can optimize their processes and achieve high-quality results.